Kodiak Wireline Core Drilling Rods

Wireline drill rods for your standard and thin walled wireline coring applications:

• Cold-drawn seamless steel tubing of very high mechanical resistance, a steel of exceptional performance unequaled on the market.

• This exceptional mechanical resistance is on the full length of the rods.

• Straightness and Hoop Stress controlled tubing.

• Surface treatment on pin threads to prevent galling.

Available in several threaded ranges :

• The standards rods (A-WL, B-WL, N-WL, H-WL, P-WL, P/HWT-WL,140WL).

• The thin walled rods (BTW, NTW).

• NEW generation of high performance WL rods.

And friction welded :

• The heavy duty rods (70HD, 94HD, & KODIAK RR)

Some Examples:

Technidrill in SOUTH-AFRICA : coring made with our Kodiak + N-WL rods in 1353m depth for 2000m goal !

Standard wireline core drilling rods

Wireline drill rods for your standard and thin walled wireline coring applications:

- Cold-drawn seamless steel tubing of very high mechanical resistance, a steel of exceptional performance unequaled on the market.

- This exceptional mechanical resistance is on the full length of the rods.

- Straightness and Hoop Stress controlled tubing.

- Surface treatment on pin threads to prevent galling.

Thin walled wireline core drilling rods

WL rods for thin wall wireline coring applications:

- Seamless cold-drawn tubes with very high mechanical resistance, an ultra-high-performance quality steel, unequaled on the market

- This exceptional mechanical resistance is over the entire length of the rods

- Straightness and residual stresses controlled

- Surface treatment on male threads for anti-galling

Heavy duty wireline core drilling rods

For deep hole applications down to 3000 meters, we propose our heavy duty range of drill rods.

Characteristics :

- Mid body of cold-drawn seamless steel tubing.

- Friction welded end pieces of specially treated steel with very high mechanical resistance.

- Specific thread design for deep hole drilling with very high resistance as to torque and as to extension.

- Straightness and Hoop Stress controlled tubing.

- Surface treatment on pin threads to prevent galling.

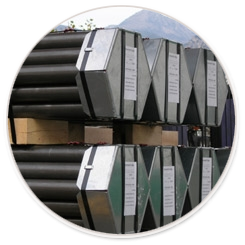

The packaging rods polls

The packaging we use for our coring rods has been studied in such a way as to satisfy the following points:

- Hexagon shaped packaging for better stability.

- Robust packaging for protection of male and female threads (Galvanized steel casing + plastic protection on the threads using protectors or bottom plate)

- Use of wooden wedges to facilitate the handling of the bales by forklift.

- Identification of products directly on the boot to facilitate shipping and reception at the customer.